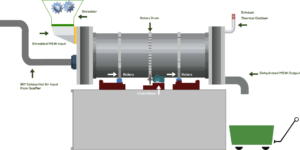

Initial MSW Handling

Municipal Solid Waste is unloaded from Garbage Trucks onto a Conveyor System.

Hopper Loading

Waste passes through a hopper to a shredder for pretreatment, reducing size before drying.

Transfer to Rotary Dryer

Shredded waste is fed into a drum dryer maintained at 90°C using gasifier heat, reducing moisture content from 50% to a dry, processable form. This enhances efficiency for downstream conversion.

Thermal Oxidation

Moisture and volatile vapors are sent to a thermal oxidizer for safe and compliant disposal.

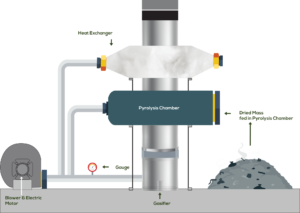

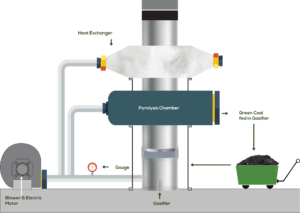

Transfer to Patented Pyrolysis Chamber

Dried waste enters a patented pyrolysis chamber for thermal decomposition. At 350°C, it produces Green Coal; at 700°C, Syngas and inert carbon.

Transfer to Patented Gasifier

Green coal powers the gasifier, creating a self-sustaining, closed-loop system that runs without external energy.

Fly Ash Generation

Fly Ash from Gasification (≈5% of input) is repurposed with Sand & Cement to create Eco-friendly Bricks & Pavers, supporting Sustainable Construction.

01. What is GD Environmental Private Limited (GDEPL)?

GD Environmental Private Limited (GDEPL) is a Pune-based company specializing in sustainable waste management solutions. We design and manufacture advanced waste-to-energy systems, including the patented Tri Fusion Dryer with Gasification & Pyrolysis and Plastic Pyrolysis Technology, to convert Municipal Solid Waste (MSW) into valuable by-products like, Drop-in Fuel, Biochar, Fly Ash Bricks and Green Coal.

2. How does the GDEPL Technology work?

The GDEPL Technology utilizes the Tri Fusion Dryer with Gasification & Pyrolysis to convert various types of waste, including Legacy Landfill waste, Inert waste, Reject waste, Mixed Waste, Dry Waste, Wet Waste, Refused Derived Fual (RDF), Municipal Solid Waste, & Plastic waste, into valuable byproducts such as Diesel, Biochar, Green Coal, and more. The process involves a combination of Dehydration, Pyrolysis, and Gasification to efficiently process waste with near-zero emissions and no residual landfill.

2. What is the difference between Gasification and Incineration?

Gasification is a process that converts waste materials into syngas (synthetic gas) through high-temperature reactions in a low-oxygen environment. This syngas can be used for electricity generation or as a fuel.

Incineration, on the other hand, involves burning waste in the presence of oxygen, which leads to the direct release of CO2 and other pollutants. Gasification is more environmentally friendly and energy-efficient than incineration.

3. Does the Tri Fusion Dryer with Gasification & Pyrolysis generate pollution?

No, the Tri Fusion Dryer with Gasification & Pyrolysis is designed to operate with minimal environmental impact. The process is conducted in a controlled, low-oxygen environment that prevents the formation of harmful pollutants. Additionally, any gases produced are used within the system.

4. Can the GDEPL Tri Fusion Dryer with Gasification & Pyrolysis work in heavy rains?

Yes, the Tri Fusion Reactor Gasifier is designed to operate under various weather conditions, including heavy rains. The system is enclosed and weatherproof, ensuring continuous operation and protection of the machinery and waste materials.

5. Does the GDEPL Tri Fusion Reactor Gasifier need heavy maintenance?

The Tri Fusion Reactor Gasifier is designed for durability and low-maintenance operation. Routine maintenance is required to ensure optimal performance, but the system is engineered to minimize downtime and operational interruptions.

6. How much electricity does the Tri Fusion Reactor Gasifier consume?

The electricity consumption of the Tri Fusion Reactor Gasifier varies depending on the scale of the operation and the type of waste processed. However, the system is designed to be energy-efficient, and in many cases, the syngas produced can be used to generate electricity, offsetting some of the energy requirements.

For Example, for a 10 TPD Tri Fusion Reactor Gasifier TFRG 18 Units / Hour is required.

7. What are the Responsibilities of Urban Bodies/Local Authorities in India?

Urban bodies and local authorities are responsible for ensuring a continuous supply of waste materials for processing, providing necessary infrastructure support, and facilitating the collection and transportation of waste to the processing facility. They are also responsible for obtaining the required statutory clearances and ensuring compliance with environmental regulations.

8. What are the Statutory Clearances or Applicable Acts in India?

The installation and operation of a Tri Fusion Reactor Gasifier require various statutory clearances, including:

- Consent to Establish (CTE) and Consent to Operate (CTO) from the State Pollution Control Board.

- Environmental Impact Assessment (EIA) clearance for large-scale projects.

- Compliance with the Municipal Solid Waste Management Rules, 2016.

- Adherence to the guidelines of the Ministry of Environment, Forest, and Climate Change (MoEFCC).

- Necessary fire safety and building permissions as per local regulations.

9. What types of waste can be processed in the Tri Fusion Reactor Gasifier?

The Tri Fusion Reactor Gasifier is versatile and can process various types of waste, including wet, dry, mixed municipal solid waste, legacy landfill waste, plastic waste (including polystyrene), and more. The system is adaptable to different waste compositions to maximize resource recovery.

10. What are the byproducts of the Tri Fusion Reactor Gasifier, and how are they used?

The key byproducts of the Tri Fusion Reactor Gasifier include:

- Syngas: Used for electricity generation, heating, or as a commercial fuel.

- Biochar: Used as a soil amendment or in moss-growing concrete.

- Green Coal: A clean alternative to conventional coal, used in industrial applications.

- Fly Ash Bricks: Used in construction for pavement and wall cladding.

- Sty Paint: Derived from processed waste, suitable for external use and waterproofing.

- Fuel Pellets/Green Coal Pellets: Used as a renewable energy source.

11. How long does it take to install and commission the Tri Fusion Reactor Gasifier?

The manufacturing of the Tri Fusion Reactor Gasifier typically requires 3 months. Additional time should be accounted for transportation, installation, and commissioning, which varies depending on the location.

12. Is training provided for operating the Tri Fusion Reactor Gasifier?

Yes, GDEPL offers comprehensive training for operators and maintenance personnel to ensure the smooth operation of the Tri Fusion Reactor Gasifier. The training covers safety protocols, routine maintenance, and efficient operation of the system.

13. Can the byproducts of the Tri Fusion Reactor Gasifier be sold commercially?

Yes, the byproducts such as syngas, biochar, green coal, and fly ash bricks have commercial value and can be sold to various industries. GDEPL can assist with market connections and potential buyers for these byproducts.

14. What types of waste plastic can the Tri Fusion Reactor Gasifier process?

The Tri Fusion Reactor Gasifier is capable of processing a wide range of waste plastics, including low-density polyethylene (LDPE), high-density polyethylene (HDPE), polypropylene (PP), polystyrene (PS), and more. Specific plastics like polystyrene, which yield higher amounts of oil, are particularly suitable for this technology.

15. What is the expected lifespan of the Tri Fusion Reactor Gasifier?

The Tri Fusion Reactor Gasifier is built with high-quality materials and advanced engineering to ensure durability. With proper maintenance, the system can operate efficiently depending on usage and environmental conditions.

16. How much space is required to install the Tri Fusion Reactor Gasifier?

The space requirements for the Tri Fusion Reactor Gasifier depend on the capacity of the unit. A standard 1 TPD (ton per day) unit typically requires around 2000 square feet of space, including space for feedstock storage, the reactor itself, and byproduct handling areas.

17. Is the Tri Fusion Reactor Gasifier scalable?

Yes, the Tri Fusion Reactor Gasifier is highly scalable. Depending on the waste processing needs of the client, the system can be scaled up or down, from small units handling 1 TPD to larger units handling 100 TPD or more.

18. How does the system handle non-recyclable waste?

The Tri Fusion Reactor Gasifier efficiently processes non-recyclable waste, converting it into syngas, biochar, and other valuable byproducts. This ensures that even waste materials that cannot be conventionally recycled are utilized effectively, reducing the burden on landfills.

19. What is the energy output of the syngas produced, and how can it be used?

The energy content of the syngas produced by the Tri Fusion Reactor Gasifier varies depending on the input material, but it is typically in the range of 5-10 MJ/m³. Syngas can be used to generate electricity, as a fuel for industrial boilers, or for heating applications.

20. Can the system be monitored remotely?

Yes, the Tri Fusion Reactor Gasifier can be monitored with remote monitoring and control systems, allowing operators to manage and optimize the process.

21. How does the system handle wet waste?

The Tri Fusion Reactor Gasifier is capable of processing wet waste by first dehydrating it in the drying phase before gasification. This allows the system to handle mixed municipal waste that includes wet organic materials.

22. What is the cost of operating the Tri Fusion Reactor Gasifier?

The operating cost of the Tri Fusion Reactor Gasifier depends on several factors, including the type of waste processed, the energy requirements, and the local cost of electricity and labor. However, the system is designed to be cost-effective, especially when considering the revenue from byproducts.

23. How does the Tri Fusion Reactor Gasifier contribute to zero waste goals?

The Tri Fusion Reactor Gasifier supports zero waste goals by converting waste materials into valuable byproducts, thereby eliminating the need for landfill disposal. The process ensures that no residual waste is left behind, contributing to sustainable waste management practices.